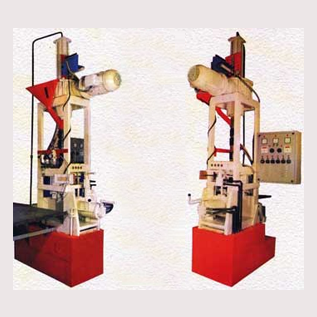

TPR Injection Moulding Machine

For the process of remoulding plastic parts, we mostly use Injection Moulding Machine. Using the TPR Injection Moulding Machine we manufacture different types of plastic products that may vary in different sizes and implementations. In the injection moulding process requires an injection moulding machine, raw plastic material, and a mould. First, the raw of plastic is melted in the injection moulding machine and after that, it is injected into the mold, where it cools and converted in a hard or solid part for the final use.

Injection moulding machine is used to mould a large part and even for a small part also. Generally, all sectors of manufacturing use injection moulded parts. The flexibility in sizes and shapes are possible in the case of production.

- It is specialized to produce various single-color, two-color soles for sports shoes, leisure shoes, sandals, slippers and so on.

- It is suitable for all types of plastic and rubber materials like PVC, TPR and TPU plastic foam and non-foam materials.

- One-time mold clamping and continuous producing injection in three-color materials can save time and energy, improve productivity and generate high profits.

- used linear telecommunication device to control injection rate, accuracy 0.1 mm.

- The hydraulic system of the machine is in high-pressure flow for making the machine much higher in efficiency and more reliable in performance.

- .The PVC/TPR/TPU injection machine used for produced three colors, two colors or single color shoe soles, outsoles, etc.

- The production rate is approximately 180 pairs per hour.

- Rapid injection units can be installed instantly to produce ultra-light high foam PVC and TPR shoe sole.

The plastic component granules are fed via a hopper into a heated barrel, melted using heater bands and the frictional action of a reciprocating screw barrel. The plastic is then injected through a nozzle into a mould cavity where it cools and hardens to the configuration of the cavity. The mould tool is mounted on a moveable platen – when the part has solidified, the platen opens and the part is ejected out using ejector pins.

After a product is designed, usually by an industrial designer or an engineers. Mouldings are made by a mouldmaker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part.

| Type | TPR Single Station | TPR Double Station | TPR Three Station |

|---|---|---|---|

| Heating Power(KW) | 4 | 8 | 12 |

| Electrical Motors Power Installed (KW) | 17 | 28 | 40 |

| Width (mm) | 625 | 1140 | 1750 |

| Length (mm) | 2610 | 2610 | 2610 |

| Productions (Pairs/Hr) | 30 to 60 | 40 to 120 | 50 to 180 |

| Total Net Weight(Kg) | 1750 | 3300 | 5050 |

| Calmping Force | 60 Tons |

|---|---|

| Injection Pressure | 140 Bars |

| Die Opening | 225 mm |

| Heating Zone | 2 |

| Colling Zone | 1 |

| L/d Screw Ratio | 14 |